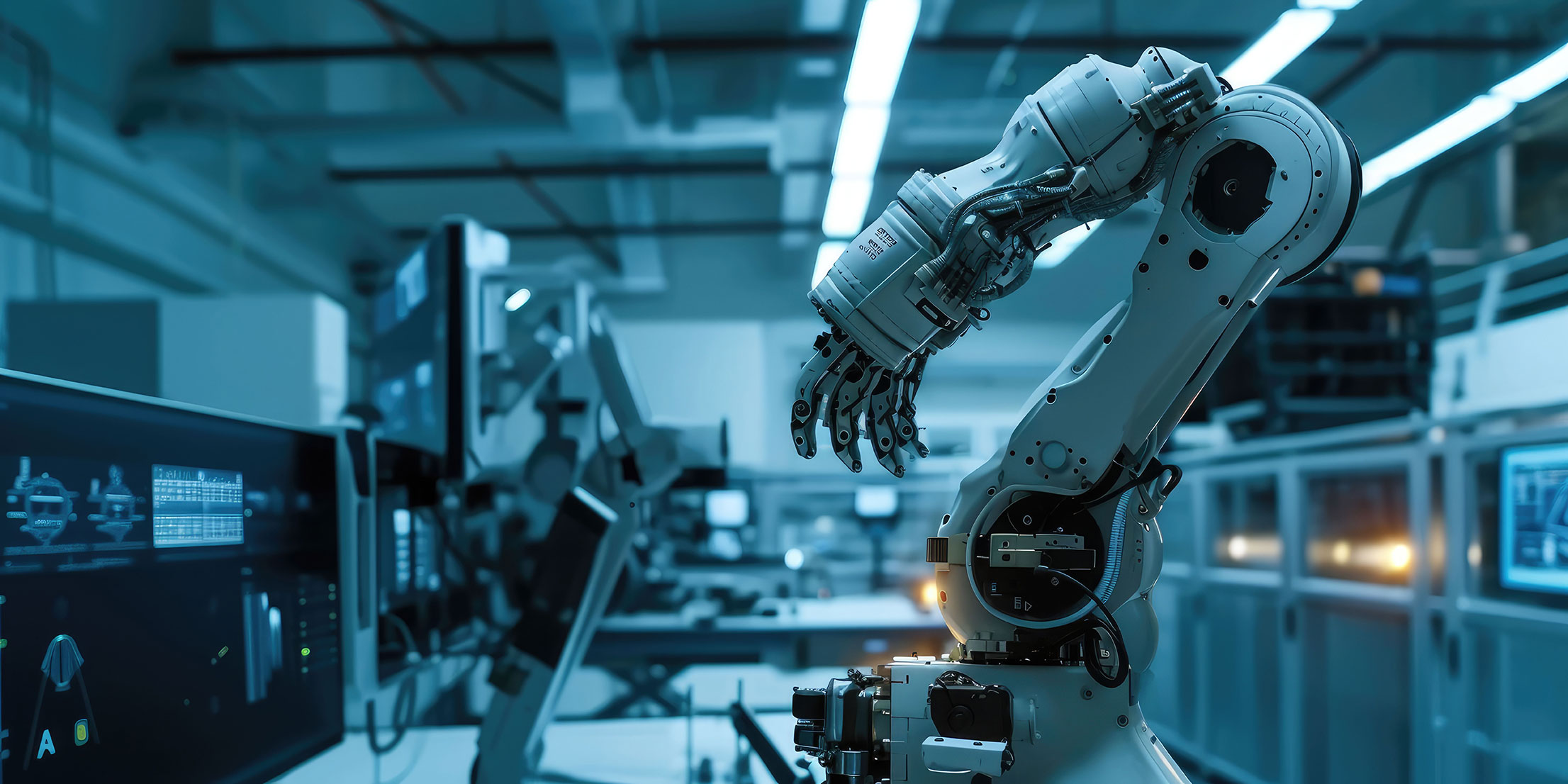

VERSA Automation

Consulting & Integration In Industrial Computing and Automation

Modernisation of industrial it

- Complete digitisation of production lines

- Specific solutions for workshop problems

- Development of user-friendly and ergonomic interfaces according to workstations

- Integration of real-time sensors aligned to the functional need: shape, volume, recognition, vision, probe, etc.

Modernisation of process and automation

- Revamping

- Real-time quality monitoring system

- Supervision

- Control and command system

- Automation project management

- Carton / bin handling: Conveyors, sorters, lifts, dynamic storage, palletisers, etc. élévateurs, Stockage dynamique, Palettiseur

Our technologies

Revamping / Reengineering the production line

– Depending on your growing needs for production flexibility, VERSA Automation Informatic Industry studies and carries out all operations to replace old or obsolete technology automation systems with modern, long-lasting solutions.

– Over the years of intervention, we have acquired rare experience in this type of operation.

– The migration is carried out in very short periods of time so as not to disrupt production.

Implementation of process automatisms

We diagnose :

– A pre-study allows us to define an architecture composed of PLCs and supervision stations.

– The functional analysis defines the organisation of the PLC programs and the functionalities of the supervisors.

We ensure project management and on-site commissioning:

– wiring

– input/output testing

– blank tests

– performance verification

– operational assistance

We carry out a transfer of skills to the users.

Creation or renovation of Industrial Computing

VERSA workshop solutions control the real-time flow of data between production machines and management IT.

Our specific developments are based on a business approach in addition to the software and hardware packages already present in the workshop and VERSA carries out :

– Study / Design

– Realization

– Setting up workstations and operational automatisms linked to industrial and management information technology

– Maintenance

Multi-expertise in integration

– Programming of the main PLCs on the market: Schneider, Siemens…

– Integration of standard, high-tech equipment, adapted to harsh workshop environments

– Peripherals integration and control (barcode readers, RFID, weight/price group, operator terminals)

– Barcode readers (Sick, Datalogic, Motorola, Symbol, Leuze …)

– Instrumentation equipment: Sensors, regulators, probes…

– Industrial terminals / Operators (Magelis, Pro-face, Siemens…)

– Printing equipment – labelling machines (Intermec, Zebra, Tec…)

– Industrial Scales (Mettler, Precia, Exa, Sartorius…)

– Weight/price groups (Bizerba, Bilanciai, Espera, Delford…)

– Touchscreen PC (Ealtec…)

– RFID